Innovative air handling unit with integrated controls and a wide range of functional sections.

|  |  |  |  |  |  |  | ||

|---|---|---|---|---|---|---|---|---|---|

Ecodesign Technical max | Rotor | Rotor w/ cooling unit | Reversible heat pump | Counter-flow exchanger | Counter-flow exchanger w/ cooling unit | Plate heat exchanger | Coil heat exchanger double-stacked | Coil heat exchanger | |

1580 | |||||||||

1540 | |||||||||

1280 | |||||||||

1250 | |||||||||

1080 | |||||||||

980 | |||||||||

850 | |||||||||

740 | |||||||||

600 | |||||||||

480 | |||||||||

400 | |||||||||

360 | |||||||||

300 | |||||||||

240 | |||||||||

190 | |||||||||

150 | |||||||||

100 | |||||||||

060 | |||||||||

m³/s 0.03.26.49.612.816.0 | |||||||||

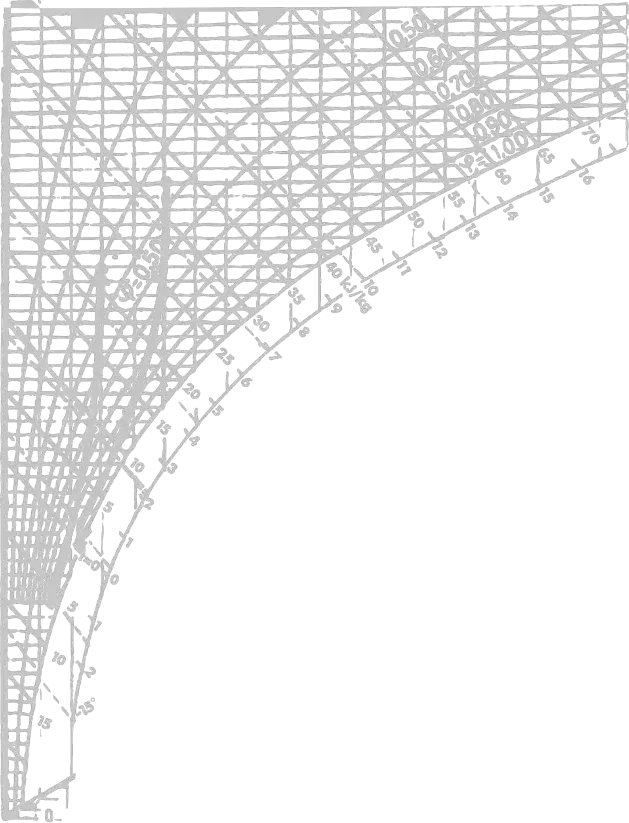

Filter within Envistar Flex

IV Produkt Designer Product selection software

Technical dataforEnvistar Flex with rotary heat exchanger

Here you will find dimensions and weights as well as power and performance information about Envistar Flex with rotary heat exchanger .

| Size | Air flow (m3/s) | Dimension (mm) | Control unit location | Weight (kg) | System voltage | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min | SFPv1,5 | Ecodesign | Max | Width | Height | Length | Width duct connection | Height duct connection | ||||

60 | 0.11 | 0.46 | 0.6 | 0.6 | 890 | 960 | 1760 | 500 | 300 | On unit roof | 395 | 400VAC |

100 | 0.17 | 0.74 | 0.99 | 1.06 | 1020 | 1090 | 1760 | 700 | 300 | On unit roof | 450 | 400VAC |

150 | 0.29 | 1.13 | 1.4 | 1.7 | 1120 | 1470 | 1980 | 800 | 500 | On unit roof | 595 | 400VAC |

190 | 0.38 | 1.59 | 1.91 | 2.2 | 1400 | 1470 | 1980 | 1000 | 500 | On unit roof | 670 | 400VAC |

240 | 0.47 | 1.91 | 2.26 | 2.6 | 1450 | 1686 | 2570 | 1000 | 600 | On unit end | 755 | 400VAC |

300 | 0.54 | 2.35 | 2.81 | 3.3 | 1666 | 1686 | 2570 | 1200 | 600 | On unit end | 835 | 400VAC |

360 | 0.66 | 2.54 | 3.11 | 3.8 | 1666 | 2060 | 2200 | 1200 | 800 | On unit end | 1020 | 400VAC |

400 | 0.66 | 3.1 | 3.56 | 4 | 1930 | 1900 | 2200 | 1400 | 700 | On unit end | 995 | 400VAC |

480 | 0.85 | 3.74 | 4.38 | 5.2 | 2040 | 2060 | 2200 | 1400 | 800 | On unit end | 1375 | 400VAC |

600 | 1.06 | 4.58 | 5.34 | 6 | 2250 | 2270 | 2200 | 1600 | 800 | On unit end | 1560 | 400VAC |

740 | 1.19 | 5.64 | 6.83 | 8.3 | 2480 | 2480 | 2820 | 2000 | 900 | In unit next to fan | 1970 | 400VAC |

850 | 1.35 | 6.95 | 8.28 | 10 | 2610 | 2740 | 2820 | 2200 | 1000 | In unit next to fan | 2200 | 400VAC |

980 | 1.66 | 7.42 | 8.93 | 10.6 | 2860 | 2890 | 2820 | 2400 | 1100 | In unit next to fan | 2485 | 400VAC |

1080 | 1.95 | 8.23 | 9.98 | 11.63 | 3000 | 3000 | 2960 | 2400 | 1100 | In unit next to fan | - | 400VAC |

1250 | 1.75 | 8.96 | 10.76 | 11.21 | 3180 | 3180 | 2960 | 2200 | 1200 | In unit next to fan | - | 400VAC |

1280 | 2.24 | 9.37 | 11.16 | 12.9 | 3180 | 3180 | 2960 | 2600 | 1200 | In unit next to fan | - | 400VAC |

1540 | 2.35 | 10.33 | 12.3 | 14.98 | 3180 | 3360 | 2960 | 2600 | 1200 | In unit next to fan | - | 400VAC |

1580 | 2.48 | 11.47 | 13.21 | 15.46 | 3500 | 3500 | 3020 | 3000 | 1200 | In unit next to fan | - | 400VAC |

Technical data for related products

Documentation forEnvistar Flex Rotary Heat Exchanger

Here you will find general documentation for this product series. Download the latest versions of product brochures, instruction manuals, certificates, and other documents.

Your air handling unit

If you are looking for information about your AHU, search using the order number.

Document | Document type | Language | Version | Download/Share | |

|---|---|---|---|---|---|

| Loading… | |||||