Envistar Top with rotary heat exchanger

Envistar Top with rotary heat exchanger

Top-connected air handling unit that saves floor space. Integrated controls and reversible heat pump with stepless cooling and heating capacity.

A top-connected duct connection is best suited in approximately 70 per cent of systems with air flow ranges up to 2.8 m3/s.

Envistar Top saves up to 75 per cent of floor space compared to a traditional installation. This makes Envistar Top the most economic and energy-efficient solution for the available floor space. Envistar Top is designed to be able to pass through narrow passages.

0.10–2.80 m3/s

0.13–2.80 m3/s

High flexibility and large air flow range

Can be controlled and monitored via cloud service

Low installation and operating costs

ODS Optimised Defrosting System ensures the highest possible annual efficiency

Option: EcoCooler with stepless control of cooling power via frequency converter

Option: The reversible heat pump ThermoCooler HP with stepless control of cooling and heating power

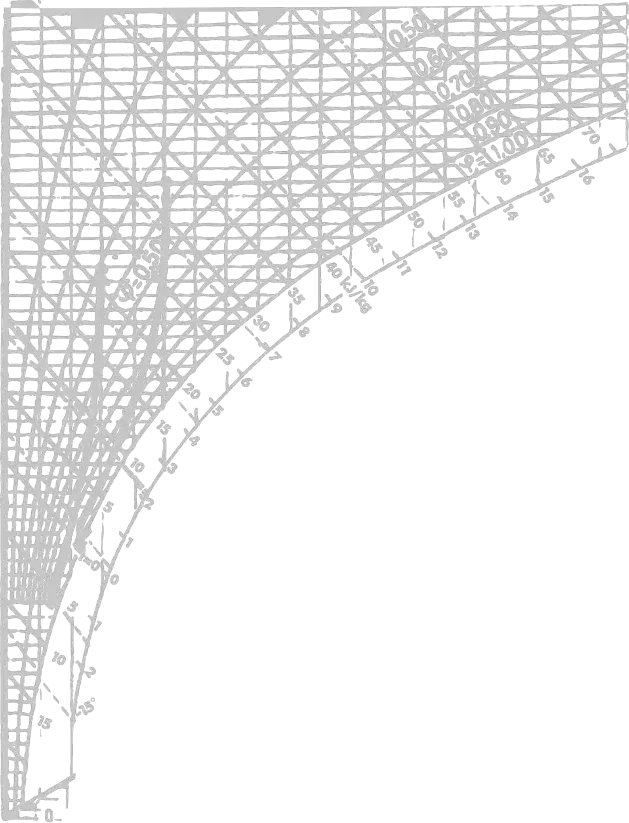

|  |  |  |  | ||

|---|---|---|---|---|---|---|

EcoDesign air flow Technical max air flow | Reversible heat pump | Rotor | Rotor w/ cooling unit | Counter-flow exchanger | Counter-flow exchanger w/ cooling unit | |

28 | ||||||

22 | ||||||

17 | ||||||

12 | ||||||

10 | ||||||

09 | ||||||

06 | ||||||

m³/s 0.00.51.01.52.02.53.0 | ||||||

Envistar Top with rotary heat exchanger

Envistar Top with rotary heat exchanger and EcoCooler

Envistar Top with rotary heat exchanger and ThermoCooler HP

Envistar Top with counter-flow heat exchanger

Envistar Top with counter-flow heat exchanger and EcoCooler

IV Produkt Designer Product selection software

For object-specific data, use our product selection software

Here you will find dimensions and weights as well as power and performance information about Envistar Top with rotary heat exchanger and ThermoCooler HP .

| Size | Cooling recovery | Air flow (m3/s) | Dimension (mm) | Weight (kg) | Refrigerant amount (kg) | Effect and fuse | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min | SFPv1,6 | Ecodesign | Max | Width | Height | Length | Width duct connection | Height duct connection | R454B Circuit 1 | tonne CO2e (R454B) Circuit 1 | Cooling effect (kW) | System voltage | |||

06-2V | - | 0.25 | 0.55 | 0.61 | 0.61 | 890 | 1910 | 1720 | 600 | 250 | 450 | 1.53 | 0.71 | 12.9 | 400VAC |

06-2V | - | 0.25 | 0.5 | 0.51 | 0.6 | 890 | 1910 | 1720 | 600 | 250 | 310 | - | - | 12.7 | - |

09-2V | - | 0.3 | 0.7 | 0.9 | 1 | 1020 | 1435 | 2790 | 700 | 300 | 630 | 2.52 | 1.17 | 15.7 | 400VAC |

10-2V | - | 0.3 | 0.8 | 0.9 | 1 | 1020 | 1980 | 1990 | 700 | 300 | 570 | 2.43 | 1.13 | 16.3 | 400VAC |

12-2V | - | 0.43 | 1.05 | 1.15 | 1.15 | 1200 | 1530 | 2790 | 900 | 300 | 730 | 3.69 | 1.72 | 23.6 | 400VAC |

17-2V | - | 0.5 | 1.45 | 1.8 | 1.8 | 1450 | 1835 | 2990 | 1000 | 350 | 940 | 5.22 | 2.43 | 28 | 400VAC |

17-2V | Yes | 0.5 | 1.45 | 1.75 | 1.75 | 1450 | 1835 | 3410 | 1000 | 350 | 1020 | 5.22 | 2.43 | 40.3 | 400VAC |

22-2V | - | 0.68 | 1.95 | 2.3 | 2.35 | 1666 | 1885 | 2990 | 1200 | 350 | 1120 | 6.01 | 2.8 | 35 | 400VAC |

22-2V | Yes | 0.68 | 1.95 | 2.25 | 2.25 | 2006 | 1885 | 3410 | 1200 | 350 | 1240 | 7.38 | 3.44 | 59.3 | 400VAC |

28-1V | - | 0.92 | 2.75 | 2.8 | 3 | 2270 | 2095 | 3090 | 1400 | 350 | 1290 | 9.66 | 4.5 | 45.7 | 400VAC |

28-2V | - | 0.92 | 2.75 | 2.8 | 3 | 2270 | 2095 | 3090 | 1400 | 350 | 1290 | 9.66 | 4.5 | 50.7 | 400VAC |

28-4V | Yes | 0.92 | 2.6 | 2.8 | 3 | 3510 | 2095 | 3510 | 1400 | 350 | 1410 | 9.66 | 4.5 | 74 | 400VAC |

Here you will find general documentation for this product series. Download the latest versions of product brochures, instruction manuals, certificates, and other documents.

If you are looking for information about your AHU, search using the order number.

Document | Document type | Language | Version | Download/Share | |

|---|---|---|---|---|---|

| Loading… | |||||

The entire range has integrated control equipment with software developed by us. We use Siemens Climatix hardware. The control equipment offers over 100 standard features to choose from so that you can optimise according to your needs. Air flow rates and temperatures can be optimised easily. The units can be connected to the web, IV Produkt Cloud or a parent system (BMS) via multiple communication protocols.

Project-specific electrical and control diagrams are included in the delivery. The unit has been function-tested and is ready for commissioning.

IV Produkt Cloud is a cloud service for our air handling units with integrated controls, giving you and your colleagues the ability to monitor your systems wherever you are.

Together, let's find the optimal solution for you!

Document | Document type | Language | Version | Download/Share | |

|---|---|---|---|---|---|

Brochure | English | 3 | |||

Brochure | English | 1 | |||

Operation and maintenance | English | 05 | |||

Operation and maintenance | English | 00 | |||

Connection instructions | English | 05 | |||

Commissioning | English | 06 | |||

Assembly instruction | English | 04 | |||

Assembly instruction | English | 00 | |||

Assembly instruction | English | - | - | ||

Configuration and settings | English | - | - | ||

Configuration and settings | English | - | - | ||

Configuration and settings | English | - | - | ||

Configuration and settings | English | - | - | ||

Configuration and settings | Swedish | 02 | - | ||

Configuration and settings | English | - | - | ||

Configuration and settings | English | - | - | ||

Configuration and settings | English | - | - | ||

Configuration and settings | English | - | - | ||

Configuration and settings | English | - | - | ||

Configuration and settings | English | - | - | ||

Configuration and settings | English | - | - | ||

Configuration and settings | English | - | - | ||

Configuration and settings | English | - | - | ||

Configuration and settings | English | - | - | ||

Configuration and settings | English | V3 | - | ||

Product sheet | English | - | |||

Certificates and declarations | English | - | - | ||

Certificates and declarations Connection instructions | English | - | - | ||

Certificates and declarations | English | - | 2025 | ||

Control code | English | - | - |